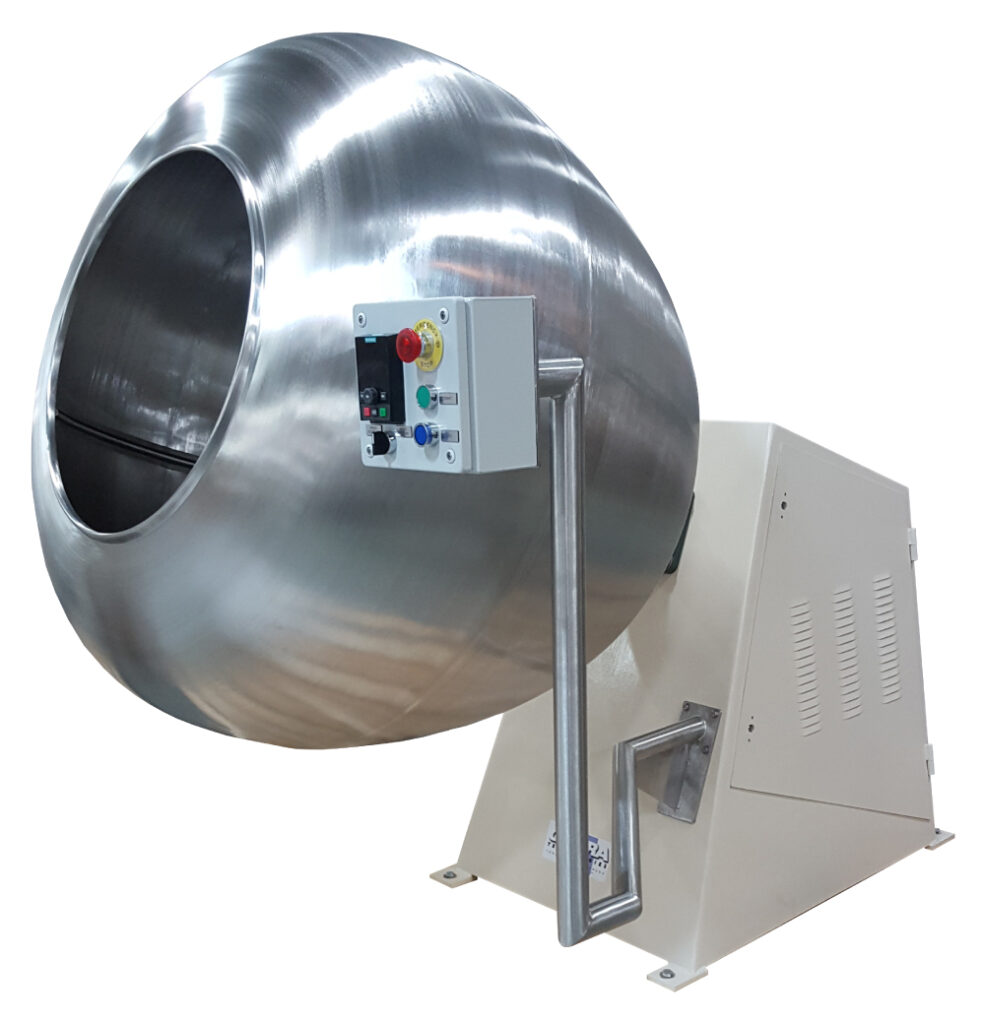

SPS Rx Coating Pans are used in a variety of industries such as Pharmaceutical, Confectionary, Food and others. they are manufactured in stainless steel and are sanitary in design. Units are available in single or in multiple pan arrangements with various capacities and options.

Standard Features:

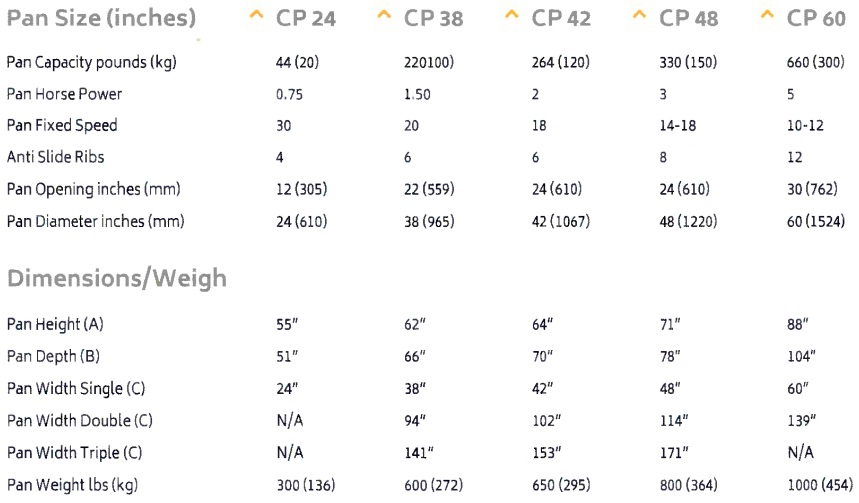

- Multiple sizes available from 24″ to 60″

- 316L stainless steel product contact

- Finish #4 polish ground smooth

- Coating pan base available in open or closed design

- 6-12 anti-slide ribs available

- Variable frequency speed drive available

- Sanitary bottom discharge valve available

- Hinged inlet/outlet air ducts with hoods available

- Quick release stainless steel spray arm with nozzles available

- Spray systems for sugar or chocolate coating applications available

- Solution preparation skids available

- Air handling unit available

- Dust collection systems available